1. Umgca osebenzayo

Le ncwadana iyasebenza ekufakelweni kwe-conveyor ye-aluminium eguquguqukayo

2. Amalungiselelo ngaphambi kokufakwa

2.1 Isicwangciso sokufakela

2.1.1 Funda imizobo yokuhlanganisa ukuze ulungiselele ukufakelwa

2.1.2 Qinisekisa ukuba izixhobo ezifunekayo ziyabonelelwa

2.1.3 Qinisekisa ukuba zonke izixhobo kunye nezinto ezifunekayo ekuhlanganiseni inkqubo yokuhambisa ziyafumaneka, kwaye ujonge uluhlu lwezixhobo

2.1.4 Qinisekisa ukuba kukho indawo eyaneleyo yomgangatho yokufaka inkqubo yokuhambisa

2.1.5 Jonga ukuba umhlaba wendawo yokufakela uthe tyaba na, ukuze zonke iinyawo zokuxhasa zikwazi ukuxhaswa ngokuqhelekileyo kumphezulu ongezantsi

2.2 Ulandelelwano lofakelo

2.2.1 Ukusarha yonke imiqadi ngobude obufunekayo kwimizobo

2.2.2 Iinyawo zokudibanisa kunye nomqadi wolwakhiwo

2.2.3 Faka imiqadi yokuhambisa kwaye uyifake kwisakhiwo senkxaso

2.2.4 Faka i-drive kunye neyunithi ye-Idler ekupheleni kwe-conveyor

2.2.5 Vavanya icandelo le-conveyor yetsheyini, jonga ukuqinisekisa ukuba akukho miqobo

2.2.6 Hlanganisa uze ufake ipleyiti yetsheyini kwi-conveyor

2.3 Ukulungiswa kwezixhobo zokufakela

Izixhobo zokufakela ziquka: isixhobo sokufaka iiphini zetsheyini, isikrweqe se-hex, isikrweqe se-hex, isikrweqe se-pistol.

2.4 Ukulungiswa kwezixhobo kunye nezixhobo

Izibophelelo eziqhelekileyo

I-slide nut

I-nati yesikwere

inathi yasentwasahlobo

Umcu wokudibanisa

3 Indibano

Izinto ezi-3.1

Ulwakhiwo olusisiseko lokuhambisa lunokwahlulwa lube ngamaqela amahlanu alandelayo

3.1.1 Ulwakhiwo lwenkxaso

3.1.2 Umqadi wokuhambisa, icandelo elithe tye kunye necandelo eligobileyo

3.1.3 Iyunithi yokuqhuba kunye ne-Idler

3.1.4 Ikhonkco eliguquguqukayo

3.1.5 Ezinye izinto ezincedisayo

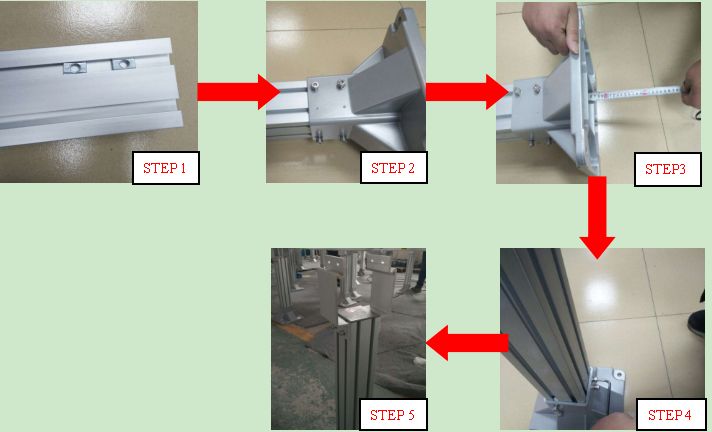

3.2 Ukufakelwa kweenyawo

3.2.1 Faka i-slider nut kwindawo ye-T yomqadi wokuxhasa

3.2.2 Faka umqadi wokuxhasa kwipleyiti yeenyawo, uze ulungise i-slider nut ebekwe kwangaphambili ngezikrufu ze-hexagon socket, uze uyiqinise ngokukhululekileyo

3.3.1 Lungisa umqadi ukusuka ezantsi konyawo ube kubungakanani obufunekayo kumzobo, okulungele ukulungiswa kobude kwixesha elizayo lokuhlanganisa

3.3.2 Sebenzisa isikrufu ukuqinisa izikrufu

3.3.3 Faka isakhelo sokuxhasa umqadi ngokufaka ipleyiti yeenyawo

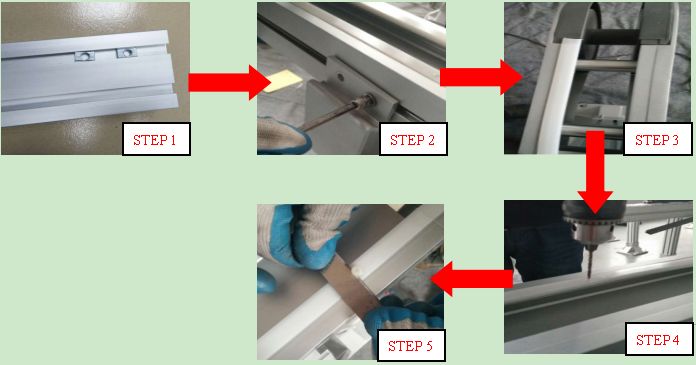

3.3 Ukufakelwa komqadi wokuhambisa

3.3.4 Faka i-slider nut kwi-T-slot

3.3.5 Okokuqala lungisa ibracket yokuqala kunye nomqadi wokuhambisa, uze utsale ibracket yesibini uyiqinise ngezikrufu

3.3.6 Ukuqala kwicala leyunithi ye-Idler, cinezela umcu wokuguguleka kwindawo yokufakela

3.3.7 Ukubethela nokucofa umcu wokugquma

3.3.8 Faka i-nut yeplastiki uze usike inxalenye eyongezelelweyo ngemela yombane

3.4 Ukufakwa nokususwa kwepleyiti yetsheyini

3.4.1 Qalisa ukufakela ipleyiti yetyathanga emva kokuba kugqityiwe ukuhlanganiswa komzimba wesixhobo, . Okokuqala, susa ipleyiti esecaleni kweyunithi ye-idler, uze uthathe icandelo lepleyiti yetyathanga, ulifake kwiyunithi ye-idler uye kwi-conveyor beam, uze utyhale ipleyiti yetyathanga ukuze ihambe ecaleni komqadi we-conveyor ukuze wenze isangqa. Qinisekisa ukuba i-conveyor assembly iyahlangabezana neemfuno

3.4.2 Sebenzisa isixhobo sokufaka iphini yetsheyini ukudibanisa iipleyiti zetsheyini ngokulandelelana, qwalasela indawo yesithuba seentsimbi zenylon ngaphandle, kwaye ucinezele iphini yentsimbi kwipleyiti yetsheyini ukuze ibe phakathi. Emva kokuba ipleyiti yetsheyini idityanisiwe, yifake kwi-conveyor beam esuka kwiyunithi ye-idler, qwalasela ipleyiti yetsheyini Indlela yokuthutha

3.4.3 Emva kokuba ipleyiti yetyathanga ijikeleze umzila wokuhambisa ukuze kwenziwe isangqa, qinisa intloko nomsila wepleyiti yetyathanga ukuze ulinganise imeko yesixhobo emva kokuhlanganiswa (akufuneki ikhululeke kakhulu okanye iqine kakhulu), qinisekisa ubude bepleyiti yetyathanga efunekayo, kwaye ususe ipleyiti yetyathanga engaphezulu (akucetyiswa ukuba isetyenziswe kwakhona)

3.4.4 Susa i-sprocket ye-Idler uze usebenzise isixhobo sokufaka i-chain pin ukudibanisa isiphelo se-chain plate ukuya esiphelweni

3.4.5 Faka i-sprocket ye-Idler kunye nepleyiti esecaleni echithwe, qaphela ukuba umcu onganyangekiyo kwipleyiti esecaleni kufuneka uhlanganiswe endaweni yawo, kwaye akunakubakho nto iphakamisayo

3.4.6 Xa ipleyiti yetsheyini yoluliwe okanye ezinye izizathu kufuneka zisuswe, amanyathelo okusebenza abuyela umva kwinkqubo yokufakela

Ixesha lokuthumela: Disemba-27-2022